| IsiXhobo kunye noHlobo | Izinto ezichanekileyo ze-elektroniki ezenziwe ngumbumba weplastiki yesitofu, | |||||

| Igama lenxalenye | Isidibanisi esiphathwayo | |||||

| Intlaka | Izinto ze-metallurgy zomgubo | |||||

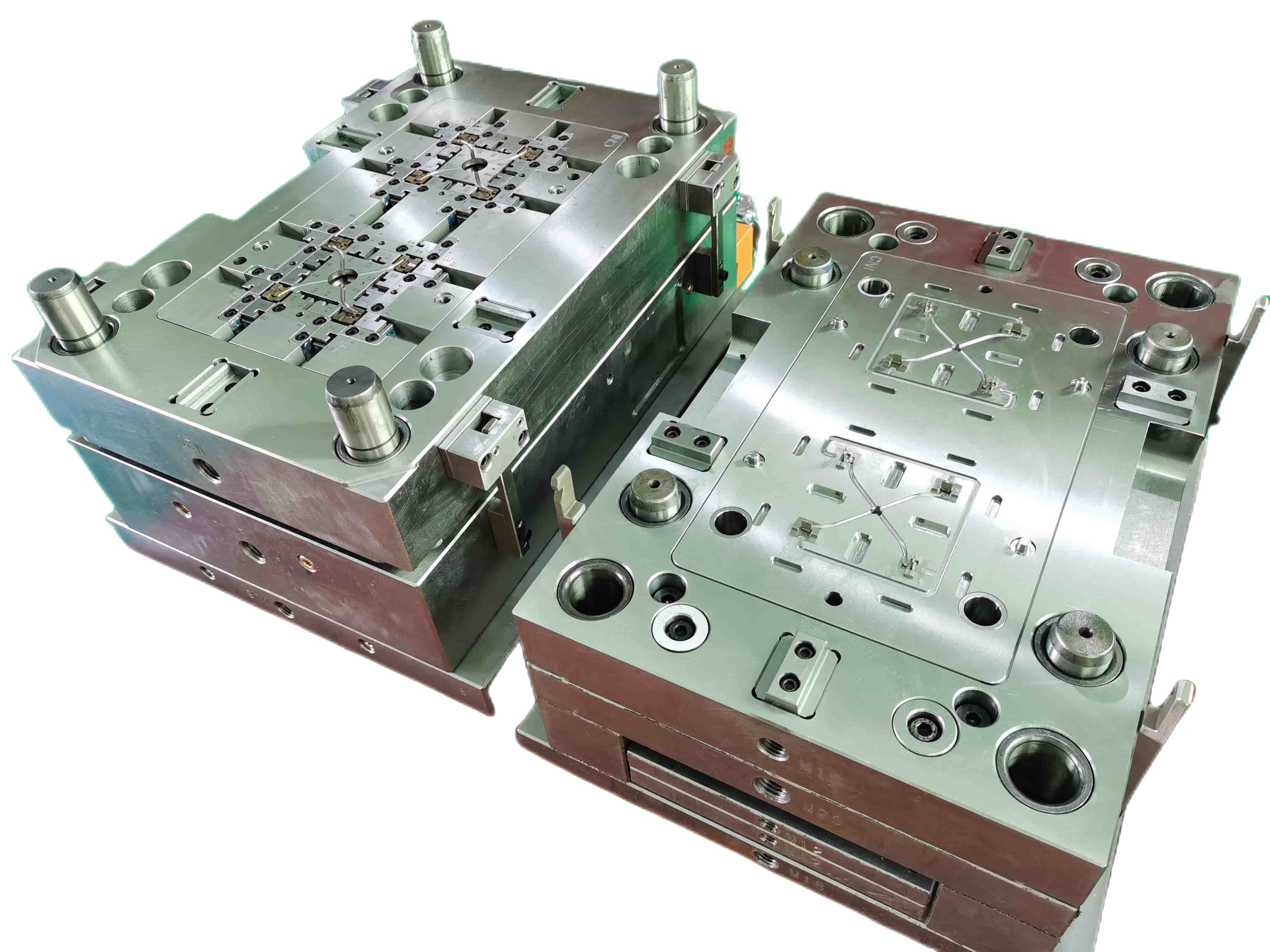

| Inani lomgodi | 1*8 | |||||

| Isiseko sokungunda | S50C | |||||

| Intsimbi yomngxunya&Core | S136 HRC 52-54 | |||||

| Ubunzima besixhobo | 450KG | |||||

| Ubungakanani besixhobo | 450X350X370mm | |||||

| Cofa iTon | 90T | |||||

| Ubomi bokungunda | 1000000 iishoti | |||||

| Inkqubo yokutofa | Imbaleki eshushu, 2pcs Mold-master iingcebiso ezishushu | |||||

| Inkqubo yokupholisa | Ukupholisa ngeoli, iqondo lokushisa lokungunda i-120 degree | |||||

| Inkqubo yokukhupha | Ukukhupha amanyathelo amabini | |||||

| Amanqaku akhethekileyo | Izixhobo zesinyithi somgubo, ukubumba ngokuchaneka kwenaliti, imbaleki eshushu, ukungunda kombhobho osi-8, ixesha elifutshane lomjikelo | |||||

| Ubunzima | Ukunyamezela ngokuchanekileyo okuphezulu, ukungunda kobushushu obuphezulu, ukubumba okufutshane okwenza ixesha lokukhokela kunye nexesha elifutshane kakhulu lomjikelo wokubumba.Izinto eziphathekayo zizinto ze-Metallurgy zePowder ezinexesha elifutshane lokupholisa kunye nesidingo esikhulu soomatshini besitofu. | |||||

| Ixesha lokukhokhela | Iiveki ezi-4 | |||||

| Iphakheji | Umngundo uhlala eTshayina kwimveliso yokubumba iplastiki | |||||

| Ukupakisha izinto | Ukuqinisekiswa kwentsimbi, i-2D yokugqibela kunye noyilo lwesixhobo se-3D, uxwebhu lwembaleki eshushu, iindawo ezisecaleni kunye nee-electrode... | |||||

| Ukuncipha | 1.005 | |||||

| Ukugqitywa komphezulu | SPI B-1 | |||||

| Ixesha lomjikelo wokubumba isitofu | 9 imizuzwana | |||||

| Unyango lwesibini lweemveliso emva kokubumba | Ukunyangwa kobushushu kwiimveliso ezibunjiweyo | |||||

| Thumela ngaphandle | Umngundo uhlala eTshayina kwimveliso yokubumba iplastiki | |||||

Ubunzima

Ukunyamezela ngokuchanekileyo okuphezulu, ukungunda kobushushu obuphezulu, ukubumba okufutshane okwenza ixesha lokukhokela kunye nexesha elifutshane kakhulu lomjikelo wokubumba.

Izinto eziphathekayo zizinto ze-Metallurgy zePowder ezinexesha elifutshane lokupholisa kunye nesidingo esikhulu soomatshini besitofu.

Yintoni i-powder metallurgy?

I-Metallurgy yomgubo yinkqubo yokuvelisa esebenzisa ukuxinzezeleka koxinzelelo kunye nokucwiliswa kwamasuntswana esinyithi ukwenza iinxalenye ezahlukeneyo kunye namalungu.Inkqubo ibandakanya ukudibanisa kunye iintsimbi ezinomgubo ezifana nentsimbi, i-aluminium, i-bronze, insimbi engenasici kunye ne-cobalt kunye ne-lubricants kunye nee-agent ezibophezelayo ngaphambi kokuzibeka kumanqanaba aphezulu oxinzelelo.Umxube obangelwayo ke ufudunyezwe de izinto zidibane ngokwekhemikhali, zenze iinxalenye ezinamandla kakhulu kunezo zithotyiweyo okanye ezenziwe ngoomatshini.

Ngenxa yokuguquguquka kwayo, i-metallurgy engumgubo iye yanda kakhulu ekuveliseni iindawo ezintsonkothileyo ezisetyenziswa kwiimoto, kwi-aerospace kunye nakwizicelo ze-elektroniki zabathengi.

Yintoni ukungunda kobushushu obuphezulu?

Ukubumba okunobushushu obuphezulu luhlobo lwenkqubo yokubumba inaliti esebenzisa amaqondo obushushu aphakamileyo kunye noxinzelelo ukuvelisa iinxalenye ezinamandla aphezulu kunye nokuqina.Inkqubo isebenza ngokufudumeza imathiriyeli ekrwada ye-thermoplastic de inyibilike kwaye emva koko ifakwe kwi-mold evaliweyo apho ibanjwe khona phantsi koxinzelelo.Ubushushu obuvela kwintlaka etyhidiweyo edityaniswe noxinzelelo ibangela ukuba izinto zenzeke ngendlela efunwayo phambi kokupholisa.Le nkqubo ivumela ukudala iinxalenye ezinzima ezikwaziyo ukumelana nobushushu obugqithisileyo kunye neekhemikhali ezidliwayo, ezizenza zilungele ukusetyenziswa kumashishini afana neemoto, i-aerospace, izixhobo zonyango kunye ne-electronics.

Izinto zePlastiki eziqhelekileyo ziquka: i-PEEK, i-PPSU, i-ULTEM® (i-Polyetherimide, i-PEI), i-Celazole®, i-Vespel®, i-Torlon® (i-Polyamide-imide) kunye nokunye.

Uyilo lokungunda lobushushu obuphezulu bokubumba

Xa uyila iimolds zeplastiki ezinobushushu obuphezulu kubalulekile ukubandakanya imijelo yokudlulisa ubushushu kunye nokusebenzisa izikhonkwane ze-thermal ukuqinisekisa ukuba iplastiki iphola ngokulinganayo ngexesha lenkqubo yokubumba.

Ukongeza, ukukhetha izinto ezifanelekileyo zokubumba kubalulekile ekudaleni iindawo ezinokumelana namaqondo obushushu agqithisileyo ngaphandle kokuphazamiseka okanye ukuqhekeka.

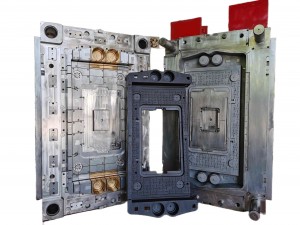

Kule projekthi, sasebenzisa intsimbi ye-S136 kunye ne-HRC 52 ~ 54, umthamo wemveliso uphezulu kakhulu, iinxalenye ze-100000pcs zazifuneka suku ngalunye, ngoko ke sasebenzisa i-8 ye-cavity mold kwaye senze iikopi ezininzi ukuhlangabezana nesicelo sobuninzi.Ukupholisa, ipholile ngeoli kwaye iqondo lokushisa lokubumba lifikelela kwi-120 degree.Ixesha lomjikelo yimizuzwana ye-9 kwaye sisebenzise i-2 step ejection yokukhutshwa kwamalungu.Le nxalenye iya kunyangwa ubushushu emva kokubumba.

Isixhobo sokungunda sokutofa yinaliti yesi-8 sokungunda kobushushu obuphezulu.

Iplastiki yimathiriyeli yomgubo wesinyithi kwaye iindawo ezibunjiweyo ziya kufuna unyango lobushushu njengoko isisinxibelelanisi esihambayo.

Ixesha lomjikelo wokubumba isitofu lifutshane kakhulu, imizuzwana eyi-9 ngokudubula okunye.

Senze izixhobo ezininzi zokukhuphela lo mthengi.Abaqulunqi bethu basebenza kakuhle kakhulu, kwi-DFM, igqitywe ngeentsuku ezi-1, ukuhlelwa kwe-2D phakathi kweentsuku ezi-2, kunye ne-3D phakathi kweentsuku ezi-3.

Ixesha lokwenziwa kokungunda ziiveki ezi-4.

Kuyilo lokungunda, xa ixesha lingxamiseke kakhulu, siqhele ukwenza umzobo we-3D ngokuthe ngqo emva kwe-DFM, kodwa kunjalo, kufuneka isekelwe kwimvume yabathengi.

Uyilo lwe-2D

Uyilo lokungunda lwe-3D

Uyilo lokungunda lwe-3D

FAQ

Ishishini lethu eliphambili lelokwenza isitofu seplastiki sokubumba, ukwenza umngundo we-die cast, ukubumba inaliti yeplastiki, ukuphosa ukufa (iAluminiyam), ukuchaneka komatshini kunye neprototyping ekhawulezayo.Sikwabonelela ngeemveliso ezongeziweyo zexabiso ezibandakanya iinxalenye zesilicon, iindawo zesitampu sesinyithi, iinxalenye ze-extrusion kunye nebala

Hayi, siyimveliso yokwenyani yokubumba kunye neplastiki yokubumba inaliti.Singanikezela ngomfanekiso wobhaliso ukuze ubhekisele kuyo kunye naluphi na olunye ulwazi olufunayo xa lufuneka.Okwangoku, ungasindwendwela nanini na, nokuba akukho madinga.

Iqela leSuntime libonelela ngenkonzo ye-24/7 isimbo sokusebenza.Ngeeholide zikawonke-wonke zaseTshayina, iintengiso zethu kunye neenjineli zinokuthatha ixesha elongezelelekileyo kulo naluphi na unxunguphalo lwakho.Kwaye xa kukho imfuneko, siya kwenza konke okusemandleni ukucela abasebenzi ukuba bathathe umsebenzi wangotshayile ngexesha leholide ngeshifti yasemini kunye neshifti yasebusuku ukuhlangabezana neemfuno zakho ezingxamisekileyo.

Sineminyaka engaphezu kweshumi amava okuthengisa kumazwe angaphandle kwimarike yehlabathi, ukungunda naliti yeplastiki kumazwe angaphandle, ukungunda die cast, iinxalenye yokujula, iimveliso ezibunjiweyo naliti yeplastiki kunye namacandelo machining CNC njl.

Ukwenziwa komngundo, sine-CNC, i-EDM, oomatshini bokugaya, oomatshini bokugaya, oomatshini bokugaya, njl.Ukubumba iplastiki yesiko, sinoomatshini besitofu aba-4 ukusuka kwiitoni ezingama-90 ukuya kwiitoni ezingama-400.Ukuhlola umgangatho, sinehexagon CMM, iProjector, tester hardness, height gauge, vernier caliper njalo njalo.

FUMANA I-DFM SIMAHLA NAMHLANJE!

-

Iprojekthi yokubumba inaliti yeplastiki evela kwi-Rapid p...

-

Ubungakanani obukhulu bokubumba inaliti yeplastiki yemoto...

-

Plastic tooling usapho ngundo iimoto umsila lig...

-

Isitofu sokungunda komngxuma omninzi kwiikepusi zepakethi...

-

Isitofu seplastiki sokungunda faka umngundo we-Automo...

-

Iglasi ephezulu yefiber yeNayiloni yesixhobo sokubumba isixhobo ...