I-aluminium die casting yinkqubo apho i-alloy ye-aluminium etyhidiweyo inyanzeliswa kwintsimbi yokufa okanye ukungunda phantsi koxinzelelo.Ngokuqhelekileyo isetyenziselwa imveliso yobuninzi kwaye inokuvelisa iinxalenye ezineenkcukacha ezintsonkothileyo kunye namacandelo anokunyamezelana okuqinileyo ngexabiso eliphantsi.Amalungu aveliswe kwi-aluminiyam yokufa kwe-aluminiyam aneempawu ezibalaseleyo zoomatshini kwaye ziyakwazi ukumelana nokubola, ubushushu kunye nokunxiba.

• Ukuphoswa kwe-aluminiyam kunika inani leenzuzo, ezinye zazo ezibandakanya:

• Izixhobo ezikhaphukhaphu neziqinileyo ezineendleko eziphezulu kunezinye iindidi zesinyithi

• Ukuphucula ukusebenza kakuhle ngenxa yamaxesha amafutshane okukhokela kunye nokuncitshiswa kwenkunkuma

• Ukunyuswa kwenkululeko yoyilo ngenxa yokonakala kwayo, ukuvumela iimilo ezintsonkothileyo zidalwe ngokukhawuleza nakulula

• Ukuxhathisa okukhulu kumhlwa, ubushushu, kunye nokuguga xa kuthelekiswa nezinye iintsimbi

• Ikhono lokuvelisa ngobuninzi, kunye ne-alloys ezininzi ze-aluminium zikwazi ukumelana noxinzelelo oluphezulu kunye namaqondo obushushu

Ukwenziwa kweAluminiyam yindlela esebenza ngeendlela ezininzi esetyenziswa ukuvelisa uluhlu olubanzi lwamacandelo ahlukeneyo kumashishini.Ukusuka kumacandelo eemoto ukuya kwizifakelo zonyango kunye nokunye, ukuphosa i-aluminiyam kungasetyenziselwa ukwenza phantse nantoni na, efana nale:

• Ushishino lweemoto:Iindidi zeendawo ezibandakanya ukusikwa kwangaphakathi, ii-casings zothumelo, iibhloko ze-injini kunye nokunyuswa, iiradiyetha, kunye neenkqubo zokutshaja.

• Ishishini le-Aerospace:Amalungu antsonkothileyo afana neempompo, izixhobo zoluvo, ii-actuator, iinqaba zikanomathotholo kunye nee-eriyali.

• Ishishini lezonyango:Amalungu akhethekileyo anje ngeevalvu zentliziyo ezifakelwayo, izixhobo zotyando, i-orthotics kunye neprosthetics.

• Izixhobo zasekhaya:Iihenjisi kunye neeletshi zeefriji kunye noomatshini bokuhlamba kunye nezinye izinto ezincinci ezifuna umsebenzi onzima.

• njl.

Ukukhetha ialluminiyam efanelekileyo kwiprojekthi yakho yokuphosa ukufa kubalulekile ekuqinisekiseni ukuba imveliso yakho egqityiweyo ihlangabezana nazo zonke iinkcukacha zakho.Nanga amanye amacebiso okukhetha ialloyi elungileyo:

• Qwalasela iimfuno zamandla kunye nokuqina kwenxalenye yakho.Ii-alloys ezahlukeneyo zinika amanqanaba ahlukeneyo amandla kunye nokumelana nokunxiba, ngoko ke kubalulekile ukukhetha i-alloy eya kuhlangabezana neemfuno zesicelo sakho.

• Vavanya umgangatho ofunekayo wokuxhathisa umhlwa.I-alloys ye-aluminiyam inokunyangwa kwaye ifakwe i-anodized ukunika ukhuseleko olongezelelweyo kwi-corrosion, ngoko ke qiniseka ukuba uqwalasela ukuba yeyiphi imo indawo oza kuyidinga ukunyamezela.

• Ukuqwalasela iindleko zemveliso namaxesha okuziswa kwazo.Ngokuxhomekeke kubunzima benxalenye, ii-alloys ezahlukeneyo zinokufuna iindlela ezahlukeneyo zokuvelisa okanye utyalo-mali lwezixhobo, ngoko ke kubalulekile ukuvavanya ezi zinto xa ukhetha ialloyi yeprojekthi yakho.

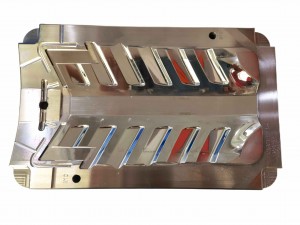

Iimfuno zezixhobo kunye nomatshini wokuphosa i-aluminium kufa ziyahluka ngokuxhomekeke kwi-alloy esetyenzisiweyo, ukuntsonkotha kwenxalenye, kunye nezinye izinto.Ngokubanzi, kubalulekile ukuqwalasela oku kulandelayo xa ukhetha uhlobo lwesixhobo:

• Ukukhetha izixhobo zesixhobo kufuneka kusekelwe kwi-alloy esetyenziswayo kunye namaqondo obushushu afunekayo ukuze kuveliswe iziphumo ezisemgangathweni.Ngokuqhelekileyo sisebenzisa i-H13, SKD61, 8407, 8418, 8433 kunye ne-W360 kwi-die cast tooling.

• Kufuneka kuthatyathwe inkathalo ukuqinisekisa ukuba kukho i-engile eyidrafti eyaneleyo ukuze amalungu abe nokusuka ngokulula kwidayizi xa ekhutshiwe.Uhlalutyo olupheleleyo lwe-DFM kufuneka lwenziwe phambi koyilo lokungunda.

• Umatshini wesibini unokufuneka emva kokwenziwa ukuze kuphunyezwe iimilo ezithile okanye iinkcukacha, kubandakanya ukwenziwa kwe-CNC, ukugrumba, ukucofa njalo njalo.

• Iinketho zokuGqiba umphezulu ezifana nokuqhunyiswa kwesanti okanye ukugudisa ngokungcangcazela, ukuthambisa, ukupeyinta okanye ukupeyinta nako kungafuneka ngokuxhomekeke kwiimfuno zakho.

CNC Machining for Die Casts Parts

Ukusombulula imiba eqhelekileyo kwi-aluminium die castings inokuba yinkqubo ethatha ixesha kunye neendleko, kodwa kubalulekile ekuqinisekiseni umgangatho wamacandelo akho.Nazi ezinye iingcebiso malunga nokusombulula imiba eqhelekileyo kunye ne-aluminium die castings:

• I-Porosity:Jonga indawo yakho kuyo nayiphi na imingxunya okanye ezinye iindawo ezinokukhokelela kwi-porosity.Ukuba ufumana nayiphi na, qiniseka ukuba uphonononga ubushushu bokubumba, uxinzelelo lwenaliti kunye nezinye izinto ezinokuthi zichaphazele ukuzaliswa kweqhekeza.

• Uphazanyiso:Ukuba ufumana ukugqwetheka kwiindawo emva kokuba zisusiwe kwifa, jonga ukuba uyilo lokungunda okanye amaxesha okupholisa anokubangela lo mba.Kusenokufuneka uhlengahlengise ezi setingi ukwenzela ukuba kuqhutywe imveliso yexesha elizayo ukuze unciphise nakuphi na ukugqwetheka.

• Iziphene zobuso:Ukuba udibana nazo naziphi na iziphene ezinje nge-splay marks okanye amaphiko, jonga ukuba kukho ukungahambelani phakathi kwesantya sokutofa kunye nesantya sokunyibilika, njengoko oku kusenokubangela le miba.Kusenokuba yimfuneko ukunyenyisa iiparamitha zokuphosa ezifana namazinga obushushu kunye nokupholisa ukuze kuncitshiswe ukungafezeki komphezulu.

Xa iprojekthi entsha iqalile, iinxalenye zeprototyping ezikhawulezayo ziyafuneka kwiintlobo zovavanyo.Zininzi iindlela zokwenza iiprototypes eziquka CNC machining, Vacuum casting, 3D printing kunye Rapid prototype tooling.

• Umatshini we-CNC unokwenza iinxalenye zentsimbi kunye neplastiki nangaluphi na ubungakanani.

• I-Vacuum Casting yeye-5-100 yeeyunithi zeplastiki zeyunithi ngokusebenzisa i-silicon molds

• Ushicilelo lwe-3D kukuprinta i-ABS, PA okanye iinxalenye zentsimbi.Kwiplastiki, iindawo eziprintiweyo ze-3D azikwazi ukumelana nobushushu obuphezulu.

• Ukwenziwa kwesixhobo somfuziselo okhawulezayo kukungunda okuthambileyo okwenziwe ngentsimbi ethambileyo efana ne-S50C okanye iAluminiyam.Esi sisombululo sinokuvelisa iindawo ezininzi kuneVacuum casting.Ixesha elikhokelayo lifutshane kunezixhobo zemveliso kwaye ixabiso lisezantsi kakhulu.

Izinto esizisebenzisileyo: Iiplastiki ezifana ne-PC, i-PMMA, i-POM, i-PP njl.Isinyithi njengentsimbi, i-aluminiyam, ubhedu, ubhedu njalo njalo.

Indlela yokwenza iinxalenye ze-silicon

Ukwenza inxalenye ye-silicone, kuya kufuneka usebenzise inkqubo yokubumba i-injection.Oku kubandakanya ukunyibilika kweplastiki kumatshini wokutofa kunye nokuyitofa kumngxuma ovaliweyo, apho ithi iphole kwaye iqine ukuze ithathe ubume obufunekayo.

Ezinye iinkqubo onokuzisebenzisa zibandakanya ukubumba ucofa, ukukhupha isifunxa, okanye ushicilelo lwe-3D.Indlela nganye ibonelela ngeenzuzo ezizodwa kunye nokungonakali kuxhomekeke kuluphi uhlobo lwenxalenye ozama ukuyenza.

Ngazo zonke iindlela, ukufumana ubushushu obufanelekileyo kunye noxinzelelo ngundoqo ekufezekiseni imilinganiselo echanekileyo kunye neempawu zezinto ezinqwenelekayo.

Izixhobo zamalungu e-silicon

Kukho amashishini amaninzi anokusebenzisa iinxalenye ezithambileyo zesilicon njengezeThutho, ezoNyango, i-Electronic, i-houseware, i-kitchenware, kunye nezinye ezininzi.Ngamacandelwana, ngokuqhelekileyo ungazifumana ezi njengeGaskets, iZitywina, ii-O-rings, izihluzi zoMoya, iiHoses, izinto zokuKhanya, iikesi zeselfowuni, izigqubuthelo zekhibhodi, iiNcingo kunye nokugqunywa kweentambo kunye nezixhobo ezininzi zoNyango.

Amalungu esinyithi sesitampu ngamalungu esinyithi adalwe ngenkqubo yokunyathela ngesinyithi, ubuchule bokuvelisa obubandakanya ukubethelwa ngenqindi, ukusika, okanye ukwenza amaphepha esinyithi abe ziimilo ezinqwenelekayo.

Isitampu sesinyithi sisetyenziselwa ukwenza iinxalenye zoluhlu olubanzi lwemizi-mveliso kubandakanya imizi-mveliso yeemoto kunye ne-aerospace.

Isenokusetyenziswa ukwenza isiko kunye neemilo ezintsonkothileyo.Izibonelelo zokusebenzisa isitampu sentsimbi ziquka ukuphumelela kweendleko, ukuqulunqwa kobunzima kunye nokuguquguquka.

I-SPM incede abathengi kwiimpahla ezininzi zetsimbi zentsimbi kwiprojekthi yabo ye-turnkey, inkonzo yethu yobunjineli esebenzayo inokugcina iindleko ezininzi kunye nexesha.

Iijigs kunye nezixhobo ezisetyenziselwa ukuncedisa kwinkqubo yokuvelisa iindawo ezahlukeneyo kunye namacandelo.

I-jig sisixhobo esikhethekileyo esinceda ukukhokela, ukubamba, okanye ukubeka i-workpiece kwindawo ngexesha lemisebenzi eyahlukeneyo yomatshini, njengokugrumba, ukugaya, kunye nokubunjwa.

Ukulungiswa zizixhobo ezincanyathiselwe kumatshini okanye kwibhentshi yokusebenzela kwaye zinceda ekufumaneni nasekukhuseleni iindawo ngelixa zisetyenzwa.

Ziyakwazi ukuba zenziwe ngokwesiko ukulungiselela imisebenzi eyahlukeneyo yokuqinisekisa ukuchaneka kunye nokusebenza kakuhle.Zombini iijigs kunye nezixhobo zingenziwa ngetsimbi ezifana nentsimbi okanye i-aluminium kwaye ziyimfuneko ekuveliseni amacandelo achanekileyo kunye nomgudu omncinci.

I-SPM yenza iijigs kunye nokulungiswa kwemveliso yethu yokubumba inaliti kwaye ikwabonelela ngenkonzo yokuyenza kubathengi.

Ukuba unemfuno yoku, nceda uqhagamshelane nangaliphi na ixesha.

FUMANA ISICATSHULWA NGENGXESHA NGOKU!

-

Isitofu sokungunda komngxuma omninzi kwiikepusi zepakethi...

-

Plastic tooling usapho ngundo iimoto umsila lig...

-

I-CNC yokugaya kunye nokuguqula abathengisi bomatshini

-

umenzi wokungunda inaliti yeplastiki, die castin...

-

Inkonzo yokubumba yesitofu yePlastiki yesiko

-

Isitofu seplastiki sokungundo esichanekileyo somthengi ...